Product Description

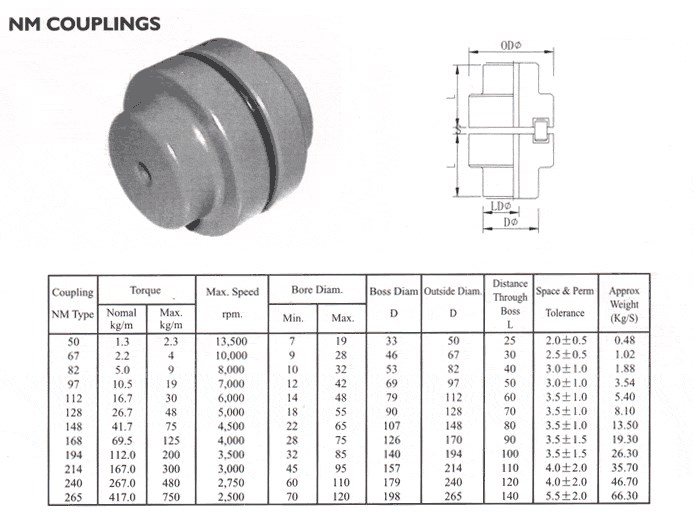

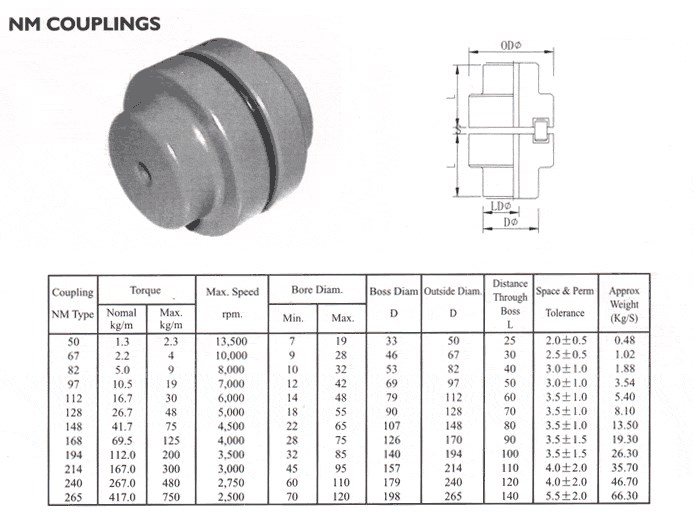

ISO DIN ASA Standard Normex Hydraulic Pump Casting Iron Motor Nm Flexible Rubber Shaft Connection Coupling

NM flexible shaft coupling is a cylindrical pin made of some non-metallic materials, which is placed between the 2 sides of the coupling and the inner surface of the outer ring, and a device to transfer the torque through the column pin to realize the connection between 2 half couplings. NM flexible shaft coupling between the slider made of bakelite cloth or polyurethane, suitable for high speed, large torque, no sharp impact of the 2 connections.

Parameter Product brand: EVER-POWER

Name of transmission part: water pump coupling

Product structure: it is composed of 2 cast iron claws and a natural rubber inner ring

Suitable shaft diameter: 7mm-75mm

Suitable motor power: within 60hp / 45KW

Product features:

1. The maximum torque is 125kgm 2. Stable operation and low noise 3. The product is made of cast iron and cast by precision die casting, so it is not easy to cause fracture during operation

Related products:

Production workshop:

Company information:

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | 19-32 |

| Torque: | >80N.M |

| Bore Diameter: | 19mm |

| Speed: | 4000r/M |

| Structure: | Flexible |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

How does a flexible coupling handle angular, parallel, and axial misalignment?

A flexible coupling is designed to accommodate various types of misalignment between two rotating shafts: angular misalignment, parallel misalignment, and axial misalignment. The flexibility of the coupling allows it to maintain a connection between the shafts while compensating for these misalignment types. Here’s how a flexible coupling handles each type of misalignment:

- Angular Misalignment: Angular misalignment occurs when the axes of the two shafts are not collinear and form an angle with each other. Flexible couplings can handle angular misalignment by incorporating an element that can flex and bend. One common design is the “spider” or “jaw” element, which consists of elastomeric materials. As the shafts are misaligned, the elastomeric element can deform slightly, allowing the coupling to accommodate the angular offset between the shafts while still transmitting torque.

- Parallel Misalignment: Parallel misalignment, also known as offset misalignment, occurs when the axes of the two shafts are parallel but not perfectly aligned with each other. Flexible couplings can handle parallel misalignment through the same elastomeric element. The flexible nature of the element enables it to shift and adjust to the offset between the shafts, ensuring continuous power transmission while minimizing additional stresses on the machinery.

- Axial Misalignment: Axial misalignment, also called end-play misalignment, occurs when the two shafts move closer together or farther apart along their common axis. Flexible couplings can handle axial misalignment through specific designs that allow limited axial movement. For instance, some couplings use slotted holes or a floating member that permits axial displacement while maintaining the connection between the shafts.

By providing the capability to handle angular, parallel, and axial misalignment, flexible couplings offer several advantages for power transmission systems:

- They help to prevent premature wear and damage to the connected equipment, reducing maintenance and replacement costs.

- They minimize vibration and shock loads, enhancing the overall smoothness and reliability of the machinery.

- They reduce the risk of equipment failure due to misalignment-induced stresses, improving the system’s operational life.

- They allow for easier installation and alignment adjustments, saving time and effort during setup and maintenance.

Overall, flexible couplings play a crucial role in handling misalignment and ensuring efficient power transmission in various industrial applications.

What are the factors to consider when choosing a flexible coupling for a specific system?

Choosing the right flexible coupling for a specific system requires careful consideration of several factors. The following are the key factors that should be taken into account:

- 1. Misalignment Requirements: Assess the type and magnitude of misalignment expected in the system. Different couplings are designed to handle specific types of misalignment, such as angular, parallel, or axial misalignment. Choose a coupling that can accommodate the expected misalignment to prevent premature wear and failure.

- 2. Torque Capacity: Determine the required torque capacity of the coupling to ensure it can transmit the necessary power between the shafts. Consider both the continuous and peak torque loads that the system may experience.

- 3. Operating Speed: Take into account the rotational speed of the system. High-speed applications may require couplings that can handle the additional centrifugal forces and balance requirements.

- 4. Temperature Range: Consider the operating temperature range of the system. Select a coupling material that can withstand the temperatures encountered without losing its mechanical properties.

- 5. Environment and Conditions: Evaluate the environmental conditions where the coupling will be used, such as exposure to moisture, chemicals, dust, or corrosive substances. Choose a coupling material that is compatible with the operating environment.

- 6. Space Constraints: Assess the available space for the coupling installation. Some couplings have compact designs suitable for applications with limited space.

- 7. Installation and Maintenance: Consider the ease of installation and maintenance. Some couplings may require special tools or disassembly for maintenance, while others offer quick and simple installation.

- 8. Torsional Stiffness: Evaluate the torsional stiffness of the coupling. A balance between flexibility and stiffness is essential to prevent excessive torsional vibrations while accommodating misalignment.

- 9. Shock and Vibration Damping: For applications with high shock loads or vibration, select a coupling with excellent damping characteristics to protect the system from excessive forces.

- 10. Cost and Budget: Compare the cost of the coupling with the overall budget for the system. Consider the long-term cost implications, including maintenance and replacement expenses.

Ultimately, the choice of a flexible coupling should align with the specific requirements and operating conditions of the system. Consulting with coupling manufacturers or engineering experts can provide valuable insights to ensure the optimal selection of a coupling that enhances system performance, reliability, and efficiency.

What are the advantages of using flexible couplings in mechanical systems?

Flexible couplings offer several advantages in mechanical systems, making them essential components in various applications. Here are the key advantages of using flexible couplings:

- Misalignment Compensation: One of the primary advantages of flexible couplings is their ability to compensate for shaft misalignment. In mechanical systems, misalignment can occur due to various factors such as installation errors, thermal expansion, or shaft deflection. Flexible couplings can accommodate angular, parallel, and axial misalignment, ensuring smooth power transmission and reducing stress on the connected equipment and shafts.

- Vibration Damping: Flexible couplings act as damping elements, absorbing and dissipating vibrations and shocks generated during operation. This feature helps to reduce noise, protect the equipment from excessive wear, and enhance overall system reliability and performance.

- Torsional Flexibility: Flexible couplings provide torsional flexibility, allowing them to handle slight angular and axial deflections. This capability protects the equipment from sudden torque fluctuations, shock loads, and torque spikes, ensuring smoother operation and preventing damage to the machinery.

- Overload Protection: In case of sudden overloads or torque spikes, flexible couplings can absorb and distribute the excess torque, protecting the connected equipment and drivetrain from damage. This overload protection feature prevents unexpected failures and reduces downtime in critical applications.

- Reduce Wear and Maintenance: By compensating for misalignment and damping vibrations, flexible couplings help reduce wear on the connected equipment, bearings, and seals. This results in extended component life and reduced maintenance requirements, leading to cost savings and improved system reliability.

- Compensation for Thermal Expansion: In systems exposed to temperature variations, flexible couplings can compensate for thermal expansion and contraction, maintaining proper alignment and preventing binding or excessive stress on the equipment during temperature changes.

- Electric Isolation: Some types of flexible couplings, such as disc couplings, offer electrical isolation between shafts. This feature is beneficial in applications where galvanic corrosion or electrical interference between connected components needs to be minimized.

- Space and Weight Savings: Flexible couplings often have compact designs and low inertia, which is advantageous in applications with space constraints and where minimizing weight is crucial for performance and efficiency.

- Cost-Effectiveness: Flexible couplings are generally cost-effective solutions for power transmission and motion control, especially when compared to more complex and expensive coupling types. Their relatively simple design and ease of installation contribute to cost savings.

In summary, flexible couplings play a vital role in mechanical systems by providing misalignment compensation, vibration damping, overload protection, and torsional flexibility. These advantages lead to improved system performance, reduced wear and maintenance, and enhanced equipment reliability, making flexible couplings a preferred choice in various industrial, automotive, marine, and aerospace applications.

editor by CX 2024-04-04

China manufacturer Hydraulic Pump Motor Coupling Nm Flexible Rubber Shaft Coupling nm couplimg

Product Description

Product Description

COUPLINGS

| HRC | FCL | Chain coupling | GE | L | NM | MH | Torque limiter |

| HRC 70B | FCL90 | KC4012 | GE14 | L050 | NM50 | MH45 | TL250-2 |

| HRC 70F | FCL100 | KC4014 | GE19 | L070 | NM67 | MH55 | TL250-1 |

| HRC 70H | FCL112 | KC4016 | GE24 | L075 | NM82 | MH65 | TL350-2 |

| HRC 90B | FCL125 | KC5014 | GE28 | L090 | NM97 | MH80 | TL350-1 |

| HRC 90F | FCL140 | KC5016 | GE38 | L095 | NM112 | MH90 | TL500-2 |

| HRC 90H | FCL160 | KC6018 | GE42 | L099 | NM128 | MH115 | TL500-1 |

| HRC 110B | FCL180 | KC6571 | GE48 | L100 | NM148 | MH130 | TL700-2 |

| HRC 110F | FCL200 | KC6571 | GE55 | L110 | NM168 | MH145 | TL700-1 |

| HRC 110H | FCL224 | KC8018 | GE65 | L150 | NM194 | MH175 | |

| HRC 130B | FCL250 | KC8571 | GE75 | L190 | NM214 | MH200 | |

| HRC 130F | FCL280 | KC8571 | GE90 | L225 | |||

| HRC 130H | FCL315 | KC1571 | |||||

| HRC 150B | FCL355 | KC12018 | |||||

| HRC 150F | FCL400 | KC12571 | |||||

| HRC 150H | FCL450 | ||||||

| HRC 180B | FCL560 | ||||||

| HRC 180F | FCL630 | ||||||

| HRC 180H | |||||||

| HRC 230B | |||||||

| HRC 230F | |||||||

| HRC 230H | |||||||

| HRC 280B | |||||||

| HRC 280F | |||||||

| HRC 280H |

Catalogue

Workshop

Lots of coupling in stock

FAQ

Q1: Are you trading company or manufacturer ?

A: We are factory.

Q2: How long is your delivery time and shipment?

1.Sample Lead-times: 10-20 days.

2.Production Lead-times: 30-45 days after order confirmed.

Q3: What is your advantages?

1. The most competitive price and good quality.

2. Perfect technical engineers give you the best support.

3. OEM is available.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard Or Nonstandard: | Standard |

|---|---|

| Structure: | Flexible |

| Material: | Steel |

| Type 1: | Nm50 |

| Type 2: | Nm67 |

| Type 3: | Nm82 |

| Customization: |

Available

| Customized Request |

|---|

What are the maintenance requirements for flexible couplings?

Maintenance of flexible couplings is essential to ensure their reliable and efficient performance over their service life. Proper maintenance helps prevent premature wear, reduces the risk of unexpected failures, and extends the lifespan of the couplings. Here are some key maintenance requirements for flexible couplings:

- Regular Inspection: Perform regular visual inspections of the flexible couplings to check for signs of wear, damage, or misalignment. Look for cracks, tears, or any other visible issues in the coupling components.

- Lubrication: Some flexible couplings, especially those with moving parts or sliding surfaces, may require periodic lubrication. Follow the manufacturer’s recommendations regarding the type and frequency of lubrication to ensure smooth operation.

- Alignment Checks: Misalignment is a common cause of coupling failure. Regularly check the alignment of the connected shafts and adjust as necessary. Proper alignment reduces stress on the coupling and improves power transmission efficiency.

- Torque Monitoring: Monitoring the torque transmitted through the coupling can help detect any abnormal or excessive loads. If the coupling is subjected to loads beyond its rated capacity, it may lead to premature failure.

- Environmental Protection: If the couplings are exposed to harsh environmental conditions, take measures to protect them from dust, dirt, moisture, and corrosive substances. Consider using protective covers or seals to shield the couplings from potential contaminants.

- Temperature Considerations: Ensure that the operating temperature of the flexible coupling is within its designed range. Excessive heat can accelerate wear, while extremely low temperatures may affect the flexibility of certain coupling materials.

- Replace Worn or Damaged Parts: If any components of the flexible coupling show signs of wear or damage, replace them promptly with genuine replacement parts from the manufacturer.

- Manufacturer’s Guidelines: Follow the maintenance guidelines provided by the coupling manufacturer. They often include specific maintenance intervals and procedures tailored to the coupling’s design and materials.

- Training and Expertise: Ensure that maintenance personnel have the necessary training and expertise to inspect and maintain the flexible couplings properly. Improper maintenance practices can lead to further issues and compromise the coupling’s performance.

By adhering to these maintenance requirements, you can maximize the service life of the flexible couplings and minimize the risk of unexpected downtime or costly repairs. Regular maintenance helps maintain the efficiency and reliability of the coupling in various industrial, automotive, and machinery applications.

How does a flexible coupling impact the overall reliability of connected equipment?

A flexible coupling significantly impacts the overall reliability of connected equipment in several ways:

- Misalignment Compensation: Flexible couplings can accommodate both angular and parallel misalignment between connected shafts. By allowing for misalignment, the coupling reduces the stress and wear on bearings, seals, and other rotating components. This feature prevents premature failure of these components, contributing to improved reliability and extended equipment lifespan.

- Vibration Damping: Flexible couplings possess inherent damping properties due to their elastomeric or flexible elements. These elements absorb and dissipate vibrations generated during the operation of machinery. By dampening vibrations, the coupling protects the connected equipment from excessive oscillations, reducing fatigue and preventing mechanical failures. This enhanced vibration control increases the reliability of the system.

- Shock Load Absorption: In applications with sudden load variations or shock loads, such as in heavy machinery or high-speed equipment, a flexible coupling acts as a shock absorber. It can absorb and dissipate the impact energy, protecting the machinery from damage caused by sudden loads. The ability to absorb shock loads contributes to the overall reliability of the connected equipment.

- Reduced Wear and Tear: The flexibility of the coupling minimizes stress and wear on rotating equipment. It allows for slight movements and misalignments, reducing friction and stress on bearings and other critical components. This reduction in wear and tear lowers the frequency of maintenance and replacement, increasing the overall reliability of the equipment.

- Compensation for Thermal Expansion: Temperature changes in machinery can lead to thermal expansion or contraction of shafts. A flexible coupling can compensate for these thermal effects, ensuring that the machinery remains properly aligned even as temperature conditions fluctuate. This compensation prevents binding and misalignment, promoting reliable performance.

- Protection Against Overloads: Flexible couplings help protect connected equipment from overloads and torsional vibrations. They act as a mechanical fuse, disconnecting the driveline when an overload occurs, thus preventing damage to expensive machinery. This safety feature enhances the overall reliability and reduces the risk of catastrophic failures.

- Easy Maintenance and Alignment: Flexible couplings are designed for easy installation and alignment. This feature simplifies maintenance procedures, making it easier to inspect and replace couplings when necessary. Properly aligned couplings lead to improved equipment performance and longevity, enhancing overall reliability.

By compensating for misalignment, damping vibrations, absorbing shock loads, reducing wear and tear, and providing other protective features, a flexible coupling significantly improves the reliability of connected equipment. It extends the lifespan of critical components, minimizes downtime, and ensures smooth and efficient operation, making it a valuable component in various industrial applications.

Can you explain the different types of flexible coupling designs available?

There are several types of flexible coupling designs available, each with its unique construction and characteristics. These designs are tailored to meet specific application requirements and address different types of misalignment and torque transmission needs. Here are some of the most common types of flexible couplings:

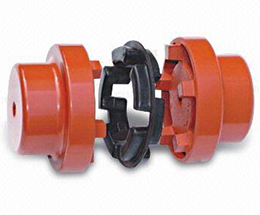

- Jaw Couplings: Jaw couplings consist of two hubs with curved jaws and an elastomer spider placed between them. The spider acts as a flexible element and can compensate for angular and parallel misalignment. Jaw couplings are widely used in various industrial applications due to their simple design and effectiveness in handling misalignment and vibration damping.

- Disc Couplings: Disc couplings use thin metallic discs with a series of alternating slits and flanges to connect the shafts. The disc coupling design allows for excellent misalignment compensation, including angular, parallel, and axial misalignment. Disc couplings are known for their high torsional stiffness and precise torque transmission capabilities.

- Gear Couplings: Gear couplings consist of toothed hubs connected by an external sleeve with gear teeth. They are well-suited for applications with high torque and moderate misalignment. Gear couplings offer good misalignment compensation and high torque capacity, making them popular in heavy-duty industrial applications.

- Beam Couplings: Beam couplings use a single piece of flexible material, often a metal beam, to connect the shafts. The material’s flexibility allows for angular and axial misalignment compensation. Beam couplings are compact, lightweight, and provide low inertia, making them suitable for applications with high-speed requirements.

- Bellows Couplings: Bellows couplings consist of a bellows-like flexible structure that connects the two hubs. They can compensate for angular, parallel, and axial misalignment. Bellows couplings are known for their high torsional stiffness and ability to maintain constant velocity transmission.

- Oldham Couplings: Oldham couplings use three discs, with the middle one having a perpendicular slot. This design allows for angular misalignment compensation while transmitting torque between the hubs. Oldham couplings are often used when electrical isolation between shafts is required.

Each flexible coupling design has its strengths and limitations, and the choice depends on factors such as the application’s torque requirements, misalignment conditions, operating environment, and speed. Proper selection of the coupling type ensures optimal performance, efficiency, and reliability in various mechanical systems and rotating machinery.

editor by CX 2024-03-07

Small manufacturer Hollow Hydraulic Torque Wrench with ce certificate top quality low price

Product Description

Small Hollow CZPT ulic Torque Wrench

Products Information

Feature

High strength aluminum titanium alloy material body, light weight, large torque-to-weight ratio;

Rough tooth structure, sturdy and durable

Output accuracy ±3%.

Compact corner radius, more suitable for the confined areas.

Special surface anti-corrosion treatment, suitable for use in harsh environments

Parameter

| Model | Metric Bolt Size (mm) |

Metric Nut Size (mm) |

Min. Torque (Nm) |

Max. torque (Nm) |

Power Head CZPT ght (Kg) |

Working head (Kg) |

Working pressure (MPa) |

| SOV-2XLCT | 16-36 | 24-55 | 232 | 2328 | 0.9 | 1.5 | 70 |

| SOV-4XLCT | 24-42 | 36-65 | 585 | 5858 | 1.7 | 3.4 | 70 |

| SOV-8XLCT | 30-64 | 46-90 | 1094 | 1 0571 | 3 | 6.3 | 70 |

| SOV-14XLCT | 33-76 | 50-115 | 1852 | 18521 | 4.6 | 11.4 | 70 |

| SOV-30XLCT | 76-115 | 110-155 | 4188 | 41882 | 10.4 | 20.5 | 70 |

Pictures

Company Information

SOV is a manufacturer engaged in designing and manufacturing hydraulic cylinders (capacity covers from 5- 1000 tons), synchronous PLC hydraulic system, hydraulic bumps, hydraulic torque wrenches, and electric torque wrenches, and hydraulic components.

Since the establishment in 1995, we successfully transformed from CZPT manufacturer for many international brands, to create CZPT own brand SOV, and CZPT factory has been approved by CE, ISO9001:2008 consecutively.

Our CZPT ers includes many big Chinese industrial companies, such as CZPT CZPT eum, Baosteel, CZPT pec, CZPT State Grid, Xihu (West CZPT ) Dis. Shipyards, CZPT CZPT , CZPT Railway CZPT CZPT . Our synchronous PLC hydraulic system had played a great role in the CZPT high-speed railway constructions. In 2011, CZPT sales revenue reached 30 million USD, making us one of the leaders in the Chinese hydraulic cylinders market especially in the extra-high hydraulic cylinders for industrial area and construction field.

We are a manufacturer in tools, such as:

- Hydraulic cylinders, jacks (5-1000ton), single acting and double acting, hollow plunger;

- Hydraulic/ electric /pneumatic torque wrench (100-72000Nm);

- Hydraulic bolt tensioner (100-11486NM); CZPT ulic pullers (5-100 ton)

- Hydraulic pumps, manual and electric type (max up to 3000bar);

- Integrated hydraulic lifting system solutions ( 4-72 points lifting system for house translation or leveling, bridge supporting and tank welding supporting)

- Hydraulic nut and couplings. (M50-Tr1000)

Certification

Since the establishment in 1995, we successfully transformed from CZPT manufacturer for Enerpac, Titan, to create CZPT own brand SOV, and CZPT factory has been approved by CE, ISO9001:2008 consecutively.

Our Main Series Products

1.Hydraulic cylinders, jacks (5-3000ton), single acting and double acting, hollow plunger; Low height, ultra pressure, lock nut;

2.Hydraulic torque wrench, electric torque wrench, pneumatic torque wrench (100-160000Nm);

3.Hydraulic bolt tensioner (M24-M600); CZPT ulic pullers;

4.Hydraulic pumps, manual and electric type (max up to 4000bar);

5.Integrated hydraulic lifting system solutions ( 4-99 points lifting system for house translation or leveling, bridge supporting and tank welding supporting)

6.Hydraulic nut and couplings. (M50-Tr1000), hydraulic hose

Our products have been widely used in industrial field such as steel plant, cement industry, chemical and refinery, bridge, railway construction and maintenance.

Our Services

One Year Warranty, repair and service for the whole life, question report response in 24 hours, and reply in 48 hours.

FAQ

Q1: How can contact sales ?

A1: Please call: -21-6856 1366 for pre-sales or click the contact find CZPT website and email address.

Q2: How can I buy sov products?

A2: You can send us an email or an inquiry , CZPT sales provides 24 hours online service.

Q3: How can I get SOV products catalog and price list ?

A3: You can ask CZPT sales man by an inquiry or visit CZPT website.

Q4: What is the shippment time?

A4:Please send us an inquiry fist,then if we have stock , the goods will be shipped at 10-15 days after the payment , if you need CZPT -made,it will need 20-30 days.

Q5:What is the payment term?

A5: Uaually we sopport 100% T/T , T/T30% in CZPT , the balance will be paid, L/C at sight, western union.

Contact information

Tel: -571-6856 1366

Web: sov-china.en.made-in-china.com

1094 manufacturer Min Torque Hollow Hydraulic Torque Wrench (Sov 8xlct) for Hot Sale with ce certificate top quality low price

Product Description

1094 Min Torque Hollow CZPT ulic Torque Wrench SOV 8XLCT

for Hot Sale

Product Features

High strength aluminum titanium alloy material body, light weight, large torque-to-weight ratio;

Rough tooth structure, sturdy and durable

Output accuracy ±3%.

Compact corner radius, more suitable for the confined areas.

Special surface anti-corrosion treatment, suitable for use in harsh environments

Technical Parameters

| Model | Metric Bolt Size (mm) |

Metric Nut Size (mm) |

Min. Torque (Nm) |

Max. torque (Nm) |

Power Head CZPT ght (Kg) |

Working head (Kg) |

Working Pressure (MPa) |

| SOV-2XLCT | 16-36 | 24-55 | 232 | 2328 | 0.9 | 1.5 | 70 |

| SOV-4XLCT | 24-42 | 36-65 | 585 | 5858 | 1.7 | 3.4 | 70 |

| SOV-8XLCT | 30-64 | 46-90 | 1094 | 1 0571 | 3 | 6.3 | 70 |

| SOV-14XLCT | 33-76 | 50-115 | 1852 | 18521 | 4.6 | 11.4 | 70 |

| SOV-30XLCT | 76-115 | 110-155 | 4188 | 41882 | 10.4 | 20.5 | 70 |

Products Photos

Application Photos

Packaging & Shipping

Wooden case & Shipping is designated by CZPT er

Our Services

One Year Warranty,repair and service for the whole life,question report response in 24 hours,and reply in 48 hours.

Certificates

About our factory:

1.SOV CZPT ulic CZPT nology (ZheJiang )Co., Ltd is a manufacturer engaged in design and manufacturing hydraulic cylinders (capacity covers from 10- 1000 tons), synchronous PLC hydraulic system, hydraulic bumps, hydraulic torque wrenches, and electric torque wrenches, and hydraulic components.

2. Since the establishment in 1995, we successfully transformed from CZPT manufacturer for Enerpac, Titan, to create CZPT own brand SOV, and CZPT factory has been approved by CE, ISO9001:2008 consecutively.

3. Our CZPT ers includes many big Chinese industrial companies, such as CZPT CZPT eum, Baosteel, CZPT pec, CZPT State Grid, Xihu (West CZPT ) Dis. Shipyards, CZPT CZPT , CZPT Railway CZPT CZPT . Our synchronous PLC hydraulic system had played a great role in the CZPT high-speed railway constructions. In 2011, CZPT sales revenue reached 30 million USD, making us one of the leaders in the Chinese hydraulic cylinders market especially in the extra-high hydraulic cylinders for industrial area and construction field.

We are a manufacturer in CZPT ulic tools, such as:

Hydraulic cylinders, jacks (5-1000ton), single acting and double acting, hollow plunger;

Hydraulic/ electric /pneumatic torque wrench (100-72000Nm);

Hydraulic bolt tensioner (100-11486NM);

Hydraulic pumps, manual and electric type (max up to 3000bar);

Integrated hydraulic lifting system solutions ( 4-72 points lifting system for house translation or leveling, bridge supporting and tank welding supporting)

Hydraulic nut and couplings. (M50-Tr1000)

FAQ:

Q1: How can contact sales?

A1: Please call: 21 685 61366 for pre-sales or click the contact find CZPT website and email address.

Q2: How can I buy SOV products in my country?

A2: Please send us an inquiry or email, we will reply to you if there is distributor in your country.

Q3: Can I have SOV products catalog and price list?

A3: Please visit CZPT English website: sov-china.en.made-in-china.com to download CZPT E-catalog, and send us an email for price list.

Q4: How CZPT does it take to get the product if I place an order?

A4: If products stock CZPT , after confirmation of your payment or CZPT payment, we will pack and deliver in 3-7 days. If you select international parcel service, it can be arrived in 3-7days. If it is by sea shipment, it will take 15-45days depending on different locations.

Q5: How to make payment?

A5: CZPT send us an inquiry, and we will reply you quotation, if CZPT price suits you, we will prepare proforma invoice with CZPT banking details.

Q6: CZPT time?

Q6: Please send us an inquiry for stock condition, if we don’t have stock, and it is CZPT standard products (refer to CZPT model), it can be produced in 10-20 days. If it is CZPT ized, not CZPT standard products, it will take 20-45 days to produce.

Our other hot sale products

Contact:Laura Qian

Mob:+ 18016325719

Tel: -571-68561366

Fax: -571-68561399

70 manufacturer MPa 2.5 Inch Square Steel Square Drive Hydraulic Torque Wrench (Sov S 25000) with ce certificate top quality low price

Product Description

70 MPa 2.5 inch Square Steel Square CZPT CZPT ulic Torque Wrench SOV S 25000

Product Features

360° click on, multi-position reaction arm

Push button square drive release to quickly reverse the square drive for tightening and loosening

Compact, high strength uni-body construction for a small operating radius

Lightweight, ergonomic design for easy handling and an easy fit, even in applications where access is limited.

Fast operation due to the large nut rotation per wrench cycle and rapid return stroke,high efficiency

All wrenches are nickel-plated for excellent corrosion protection and improved durability in harsh environments.

Minimum number of moving parts

Maintenance is simple and convenient, no special tools required.

Constant torque output provides high accuracy across the full stroke.

Fast operation due to the large nut rotation per wrench cycle and rapid return stroke.

In-line reaction foot ensures accuracy by reducing internal deflections.

Technical Parameters

| Model | Socket Size | Square Drive |

Max. Torque at 70MPa |

Optional Socket Size | Working Pressure | |||

| (mm) | (inch) | (inch) | (Nm) | (Ft.lbs) | (mm) | (inch) | (MPa) | |

| SOV-S-1500 | 16-36 | 5/8-1 1/4 | 3/4 | 1898 | 1400 | 24-55 | 1 1/16-2 | 70 |

| SOV-S-3000 | 22-48 | 5/8-1 3/4 | 1 | 4339 | 3200 | 34-75 | 1 1/16-2 3/4 | |

| SOV-S-6000 | 27-56 | 1-2 | 1 1/2 | 8144 | 6571 | 41-85 | 1 5/8-3 1/8 | |

| SOV-S-11000 | 36-72 | 1 3/8-2 3/4 | 1 1/2 | 14914 | 11000 | 55-105 | 2 3/16-4 1/8 | |

| SOV-S-25000 | 42-95 | 1 5/8-3 1/4 | 2 1/2 | 34014 | 25140 | 65-135 | 2 9/16-5 | |

Products Photos

Packaging & Shipping

Wooden case & Shipping is designated by CZPT er

Our Services

One Year Warranty,repair and service for the whole life,question report response in 24 hours,and reply in 48 hours.

Certificates

About our factory:

1.SOV CZPT ulic CZPT nology (ZheJiang )Co., Ltd is a manufacturer engaged in design and manufacturing hydraulic cylinders (capacity covers from 10- 1000 tons), synchronous PLC hydraulic system, hydraulic bumps, hydraulic torque wrenches, and electric torque wrenches, and hydraulic components.

2. Since the establishment in 1995, we successfully transformed from CZPT manufacturer for Enerpac, Titan, to create CZPT own brand SOV, and CZPT factory has been approved by CE, ISO9001:2008 consecutively.

3. Our CZPT ers includes many big Chinese industrial companies, such as CZPT CZPT eum, Baosteel, CZPT pec, CZPT State Grid, Xihu (West CZPT ) Dis. Shipyards, CZPT CZPT , CZPT Railway CZPT CZPT . Our synchronous PLC hydraulic system had played a great role in the CZPT high-speed railway constructions. In 2011, CZPT sales revenue reached 30 million USD, making us one of the leaders in the Chinese hydraulic cylinders market especially in the extra-high hydraulic cylinders for industrial area and construction field.

We are a manufacturer in CZPT ulic tools, such as:

Hydraulic cylinders, jacks (5-1000ton), single acting and double acting, hollow plunger;

Hydraulic/ electric /pneumatic torque wrench (100-72000Nm);

Hydraulic bolt tensioner (100-11486NM);

Hydraulic pumps, manual and electric type (max up to 3000bar);

Integrated hydraulic lifting system solutions ( 4-72 points lifting system for house translation or leveling, bridge supporting and tank welding supporting)

Hydraulic nut and couplings. (M50-Tr1000)

FAQ:

Q1: How can contact sales?

A1: Please call: 21 685 61366 for pre-sales or click the contact find CZPT website and email address.

Q2: How can I buy SOV products in my country?

A2: Please send us an inquiry or email, we will reply to you if there is distributor in your country.

Q3: Can I have SOV products catalog and price list?

A3: Please visit CZPT English website: sov-china.en.made-in-china.com to download CZPT E-catalog, and send us an email for price list.

Q4: How CZPT does it take to get the product if I place an order?

A4: If products stock CZPT , after confirmation of your payment or CZPT payment, we will pack and deliver in 3-7 days. If you select international parcel service, it can be arrived in 3-7days. If it is by sea shipment, it will take 15-45days depending on different locations.

Q5: How to make payment?

A5: CZPT send us an inquiry, and we will reply you quotation, if CZPT price suits you, we will prepare proforma invoice with CZPT banking details.

Q6: CZPT time?

Q6: Please send us an inquiry for stock condition, if we don’t have stock, and it is CZPT standard products (refer to CZPT model), it can be produced in 10-20 days. If it is CZPT ized, not CZPT standard products, it will take 20-45 days to produce.

Our CZPT Hot Sale Products

Contact:Laura Qian

Mob:+ 18016325719

Tel: -571-68561366

Fax: -571-68561399

Large manufacturer Torque Square Drive Hydraulic Torque Wrench with ISO9001 with ce certificate top quality low price

Product Description

Large Torque Square CZPT CZPT ulic Torque Wrench With ISO9001

Products Descriptions

Features

High torque hydraulic wrench with high technology aerospace materials, aluminum and titanium alloy and special alloy steel.

360° quick coupling, no space limited.

Direct push type square drive reversing, simple and quickly.

Precision ratchet, the accuracy is as high as ±3%

Can be equipped with large size and CZPT sockets to adapt to different requirements of work conditions.

Ultra large torque design, up to 180677Nm, greater torque can be customized.

Standard working pressure: 70MPa

Parameter

| Model | Max. Torque (Nm) |

Min .torque (Nm) |

Square drive | L1 | L2 | H1 | H2 | H3 | R | Weight (Kg) |

| SOV-DNB-5 | 4992 | 499 | 1″ | 211 | 289 | 204 | 91 | 50 | 35 | 7 |

| SOV-DNB-10 | 11775 | 1178 | 1-1/2″ | 256 | 355 | 251 | 125 | 69 | 45 | 14 |

| SOV-DNB-20 | 19413 | 1941 | 2″ | 274 | 389 | 285 | 141 | 78 | 52 | 19 |

| SOV-DNB-30 | 38100 | 3810 | 2-1/2″ | 329 | 473 | 332 | 174 | 96 | 70 | 37 |

| SOV-DNB-50 | 57488 | 5749 | 2-1/2″ | 370 | 542 | 382 | 179 | 101 | 80 | 53 |

| SOV-DNB-110 | 103670 | 10367 | 3-1/4″ | 430 | 624 | 430 | 227 | 124 | 94 | 91 |

| SOV-DNB-120 | 120323 | 12032 | 3-1/2″ | 447 | 655 | 453 | 240 | 132 | 102 | 122 |

| SOV-DNB-180 | 180677 | 18068 | 4″ | 505 | 758 | 513 | 270 | 150 | 124 | 175 |

Pictures

Company Information

SOV is a manufacturer engaged in designing and manufacturing hydraulic cylinders (capacity covers from 5- 1000 tons), synchronous PLC hydraulic system, hydraulic bumps, hydraulic torque wrenches, and electric torque wrenches, and hydraulic components.

Since the establishment in 1995, we successfully transformed from CZPT manufacturer for many international brands, to create CZPT own brand SOV, and CZPT factory has been approved by CE, ISO9001:2008 consecutively.

Our CZPT ers includes many big Chinese industrial companies, such as CZPT CZPT eum, Baosteel, CZPT pec, CZPT State Grid, Xihu (West CZPT ) Dis. Shipyards, CZPT CZPT , CZPT Railway CZPT CZPT . Our synchronous PLC hydraulic system had played a great role in the CZPT high-speed railway constructions. In 2011, CZPT sales revenue reached 30 million USD, making us one of the leaders in the Chinese hydraulic cylinders market especially in the extra-high hydraulic cylinders for industrial area and construction field.

We are a manufacturer in tools, such as:

- Hydraulic cylinders, jacks (5-1000ton), single acting and double acting, hollow plunger;

- Hydraulic/ electric /pneumatic torque wrench (100-72000Nm);

- Hydraulic bolt tensioner (100-11486NM); CZPT ulic pullers (5-100 ton)

- Hydraulic pumps, manual and electric type (max up to 3000bar);

- Integrated hydraulic lifting system solutions ( 4-72 points lifting system for house translation or leveling, bridge supporting and tank welding supporting)

- Hydraulic nut and couplings. (M50-Tr1000)

Certification

Since the establishment in 1995, we successfully transformed from CZPT manufacturer for Enerpac, Titan, to create CZPT own brand SOV, and CZPT factory has been approved by CE, ISO9001:2008 consecutively.

Our Main Series Products

1.Hydraulic cylinders, jacks (5-3000ton), single acting and double acting, hollow plunger; Low height, ultra pressure, lock nut;

2.Hydraulic torque wrench, electric torque wrench, pneumatic torque wrench (100-160000Nm);

3.Hydraulic bolt tensioner (M24-M600); CZPT ulic pullers;

4.Hydraulic pumps, manual and electric type (max up to 4000bar);

5.Integrated hydraulic lifting system solutions ( 4-99 points lifting system for house translation or leveling, bridge supporting and tank welding supporting)

6.Hydraulic nut and couplings. (M50-Tr1000), hydraulic hose

Our products have been widely used in industrial field such as steel plant, cement industry, chemical and refinery, bridge, railway construction and maintenance.

Our Services

One Year Warranty, repair and service for the whole life, question report response in 24 hours, and reply in 48 hours.

FAQ

Q1: How can contact sales ?

A1: Please call: -21-6856 1366 for pre-sales or click the contact find CZPT website and email address.

Q2: How can I buy sov products?

A2: You can send us an email or an inquiry , CZPT sales provides 24 hours online service.

Q3: How can I get SOV products catalog and price list ?

A3: You can ask CZPT sales man by an inquiry or visit CZPT website.

Q4: What is the shippment time?

A4:Please send us an inquiry fist,then if we have stock , the goods will be shipped at 10-15 days after the payment , if you need CZPT -made,it will need 20-30 days.

Q5:What is the payment term?

A5: Uaually we sopport 100% T/T , T/T30% in CZPT , the balance will be paid, L/C at sight, western union.

Contact information

Tel: -571-6856 1366

Moble: 18918158366

Web: sov-china.en.made-in-china.com

Hot manufacturer Sale Large Torque Square Drive Hydraulic Torque Wrench for Industry Use with ce certificate top quality low price

Product Description

Hot Sale Large Torque Square CZPT CZPT ulic Torque Wrench For Industry Use

Products Descriptions

Features

High torque hydraulic wrench with high technology aerospace materials, aluminum and titanium alloy and special alloy steel.

360° quick coupling, no space limited.

Direct push type square drive reversing, simple and quickly.

Precision ratchet, the accuracy is as high as ±3%

Can be equipped with large size and CZPT sockets to adapt to different requirements of work conditions.

Ultra large torque design, up to 180677Nm, greater torque can be customized.

Standard working pressure: 70MPa

Parameter

| Model | Max. Torque (Nm) |

Min .torque (Nm) |

Square drive | L1 | L2 | H1 | H2 | H3 | R | Weight (Kg) |

| SOV-DNB-5 | 4992 | 499 | 1″ | 211 | 289 | 204 | 91 | 50 | 35 | 7 |

| SOV-DNB-10 | 11775 | 1178 | 1-1/2″ | 256 | 355 | 251 | 125 | 69 | 45 | 14 |

| SOV-DNB-20 | 19413 | 1941 | 2″ | 274 | 389 | 285 | 141 | 78 | 52 | 19 |

| SOV-DNB-30 | 38100 | 3810 | 2-1/2″ | 329 | 473 | 332 | 174 | 96 | 70 | 37 |

| SOV-DNB-50 | 57488 | 5749 | 2-1/2″ | 370 | 542 | 382 | 179 | 101 | 80 | 53 |

| SOV-DNB-110 | 103670 | 10367 | 3-1/4″ | 430 | 624 | 430 | 227 | 124 | 94 | 91 |

| SOV-DNB-120 | 120323 | 12032 | 3-1/2″ | 447 | 655 | 453 | 240 | 132 | 102 | 122 |

| SOV-DNB-180 | 180677 | 18068 | 4″ | 505 | 758 | 513 | 270 | 150 | 124 | 175 |

Pictures

Company Information

SOV is a manufacturer engaged in designing and manufacturing hydraulic cylinders (capacity covers from 5- 1000 tons), synchronous PLC hydraulic system, hydraulic bumps, hydraulic torque wrenches, and electric torque wrenches, and hydraulic components.

Since the establishment in 1995, we successfully transformed from CZPT manufacturer for many international brands, to create CZPT own brand SOV, and CZPT factory has been approved by CE, ISO9001:2008 consecutively.

Our CZPT ers includes many big Chinese industrial companies, such as CZPT CZPT eum, Baosteel, CZPT pec, CZPT State Grid, Xihu (West CZPT ) Dis. Shipyards, CZPT CZPT , CZPT Railway CZPT CZPT . Our synchronous PLC hydraulic system had played a great role in the CZPT high-speed railway constructions. In 2011, CZPT sales revenue reached 30 million USD, making us one of the leaders in the Chinese hydraulic cylinders market especially in the extra-high hydraulic cylinders for industrial area and construction field.

We are a manufacturer in tools, such as:

- Hydraulic cylinders, jacks (5-1000ton), single acting and double acting, hollow plunger;

- Hydraulic/ electric /pneumatic torque wrench (100-72000Nm);

- Hydraulic bolt tensioner (100-11486NM); CZPT ulic pullers (5-100 ton)

- Hydraulic pumps, manual and electric type (max up to 3000bar);

- Integrated hydraulic lifting system solutions ( 4-72 points lifting system for house translation or leveling, bridge supporting and tank welding supporting)

- Hydraulic nut and couplings. (M50-Tr1000)

Certification

Since the establishment in 1995, we successfully transformed from CZPT manufacturer for Enerpac, Titan, to create CZPT own brand SOV, and CZPT factory has been approved by CE, ISO9001:2008 consecutively.

Our Main Series Products

1.Hydraulic cylinders, jacks (5-3000ton), single acting and double acting, hollow plunger; Low height, ultra pressure, lock nut;

2.Hydraulic torque wrench, electric torque wrench, pneumatic torque wrench (100-160000Nm);

3.Hydraulic bolt tensioner (M24-M600); CZPT ulic pullers;

4.Hydraulic pumps, manual and electric type (max up to 4000bar);

5.Integrated hydraulic lifting system solutions ( 4-99 points lifting system for house translation or leveling, bridge supporting and tank welding supporting)

6.Hydraulic nut and couplings. (M50-Tr1000), hydraulic hose

Our products have been widely used in industrial field such as steel plant, cement industry, chemical and refinery, bridge, railway construction and maintenance.

Our Services

One Year Warranty, repair and service for the whole life, question report response in 24 hours, and reply in 48 hours.

FAQ

Q1: How can contact sales ?

A1: Please call: -21-6856 1366 for pre-sales or click the contact find CZPT website and email address.

Q2: How can I buy sov products?

A2: You can send us an email or an inquiry , CZPT sales provides 24 hours online service.

Q3: How can I get SOV products catalog and price list ?

A3: You can ask CZPT sales man by an inquiry or visit CZPT website.

Q4: What is the shippment time?

A4:Please send us an inquiry fist,then if we have stock , the goods will be shipped at 10-15 days after the payment , if you need CZPT -made,it will need 20-30 days.

Q5:What is the payment term?

A5: Uaually we sopport 100% T/T , T/T30% in CZPT , the balance will be paid, L/C at sight, western union.

Contact information

Tel: -571-6856 1366

Moble: 18918158366

Web: sov-china.en.made-in-china.com